Motors with endless applications

24 and 48V BLDC Motors with PWM and Analog feedback

Automation Supply External Motors and Motor Driven Rollers can be used to drive roller and belt conveyors. Due to the small size of our motors, little to no space is lost when constructing solutions based on External Motors and Motor Driven Rollers (MDR).

Additional Services

Automation Supply can adapt the motors to match customer requirements most optimally. The following adaptations can be made within a short timeframe:

- Custom Gear ratio

- Custom Gearbox

- Custom Pulley and Drives

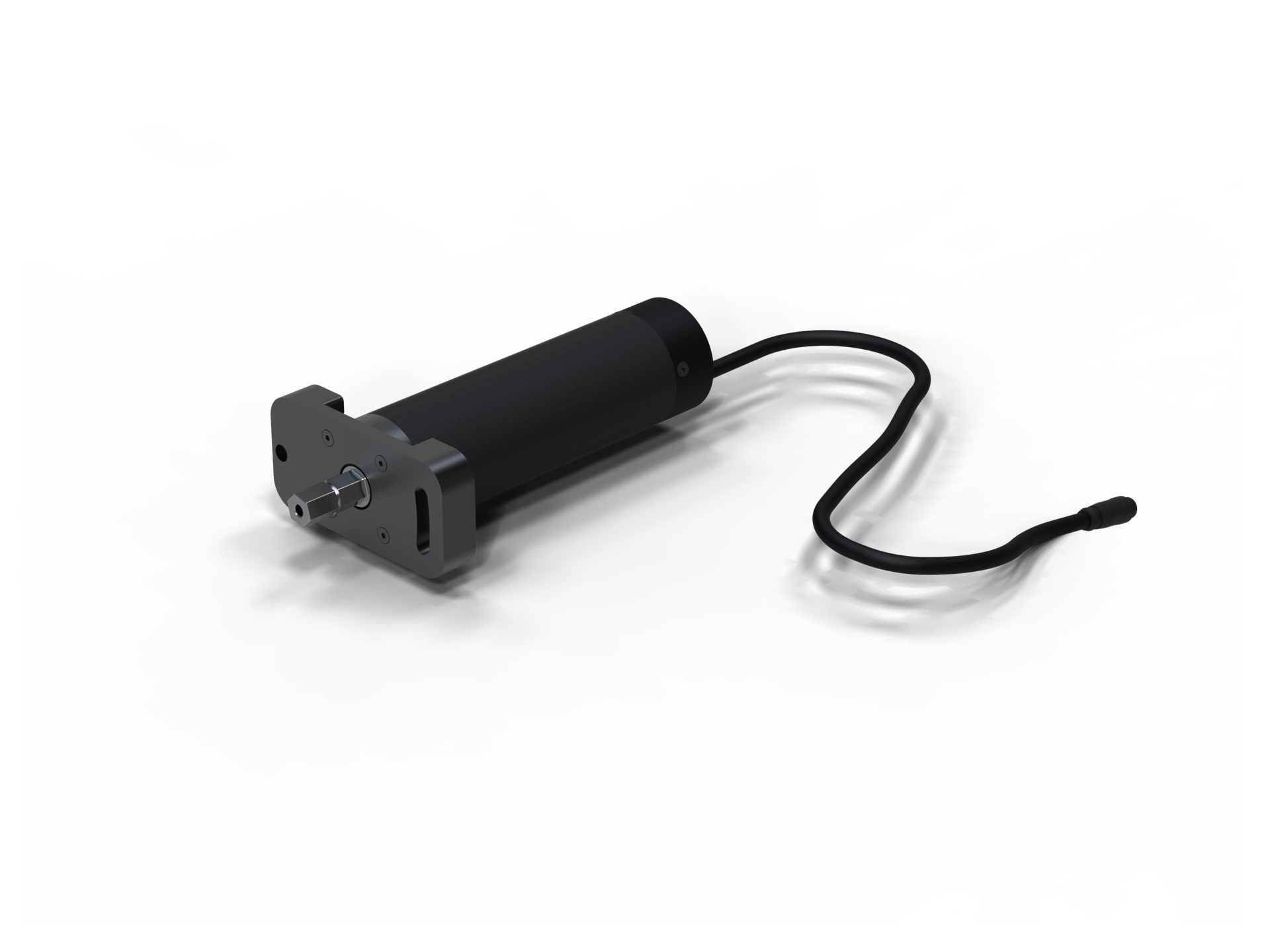

External Motors 24 and 48V

External Motors are commonly used to create roller conveyors, belt conveyors, or linear movement applications in which custom ratios and/or speed are required.

Duty Cycle: S1 | S4 900 cycles per hour at 50% duty cycle

Max Power: 90 Watts @ 24 or 48 Vdc

Input Power: 24 or 48 Vdc

Start-up Current: Max 4.5 A

Motor Speed: 6200 RPM

RPM Range: 1030 | 506 | 260 | 170 | 50 | 29

Controls: PWM 12Khz or 0-10V Analog

Motor and Mounting Bracket: Included

Power Supply: Not Included

Controller: Not Included

Control Box and Cables: Not Included

Upon request: Lagging | Spindle | Bracket Adaptation | RPM Change

Motor Driven Roller (MDR)

Motor Driven Rollers are used to create simple roller en belt conveyor construction designed for modular builds and hot swapping in the field.

Duty Cycle: S1 | S4 900 cycles per hour at 50% duty cycle

Max Power: 90 Watts @ 24 or 48 Vdc

Input Power: 24 or 48 Vdc

Start-up Current: Max 4.5 A

Motor Speed: 6200 RPM

RPM Range: 1030 | 506 | 260 | 170 | 50 | 29

Controls: PWM 12Khz or 0-10V Analog

Motor and Mounting Bracket: Included

Power Supply: Not Included

Controller: Not Included

Control Box and Cables: Not Included

Upon request: Spindle | Bracket Adaptation | RPM Change